Recycling

Our flooring deserves an afterlife.

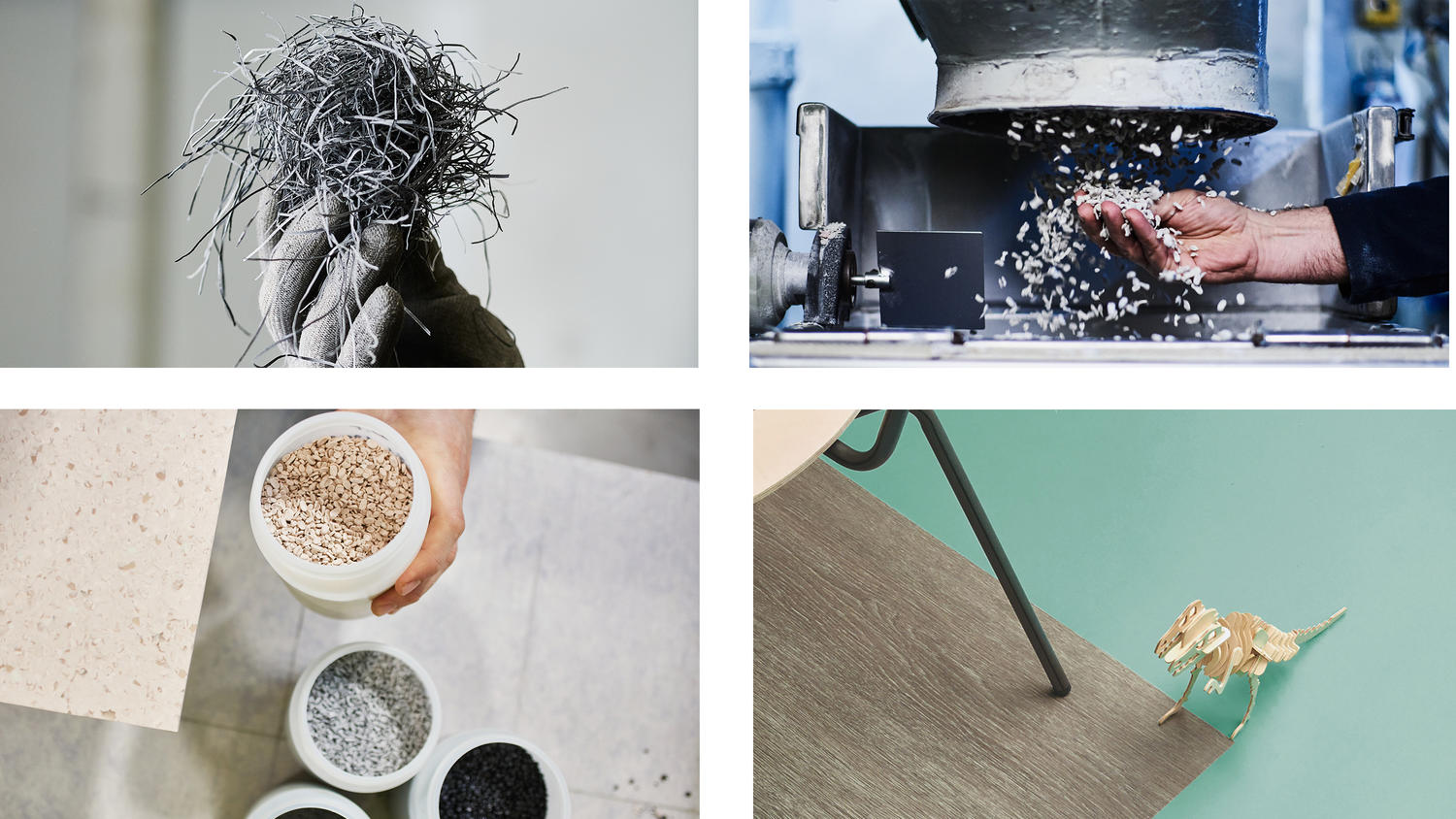

Recycling the vinyl and linoleum off-cuts from production and installation is a no-brainer. These are nice, clean scraps of material that are straightforward to recycle. Easy. But how to recycle used flooring when it comes to the end of its life? Often covered in glue, bits of concrete and other chemical residues from years of use and, most importantly, how to reintroduce it into our supply chain with 100% safety guaranteed? Now there’s a challenge! But it’s one we’re rising to. We eco design our products with end of life in mind, for example developing glue-free solutions that promote easy recycling. Our recycling teams are also continually developing innovative new ways of recycling more and more used materials in our eight dedicated recycling centres around the world.

For example, we've developed pioneering techniques that clean, shred and recycle previously unusable glued post-use homogeneous vinyl* (closed loop). That’s something no other European flooring manufacturer can say, and it’s a game changer. Moreover, we are the only flooring manufacturer to recycle post-use linoleum, an industry first.

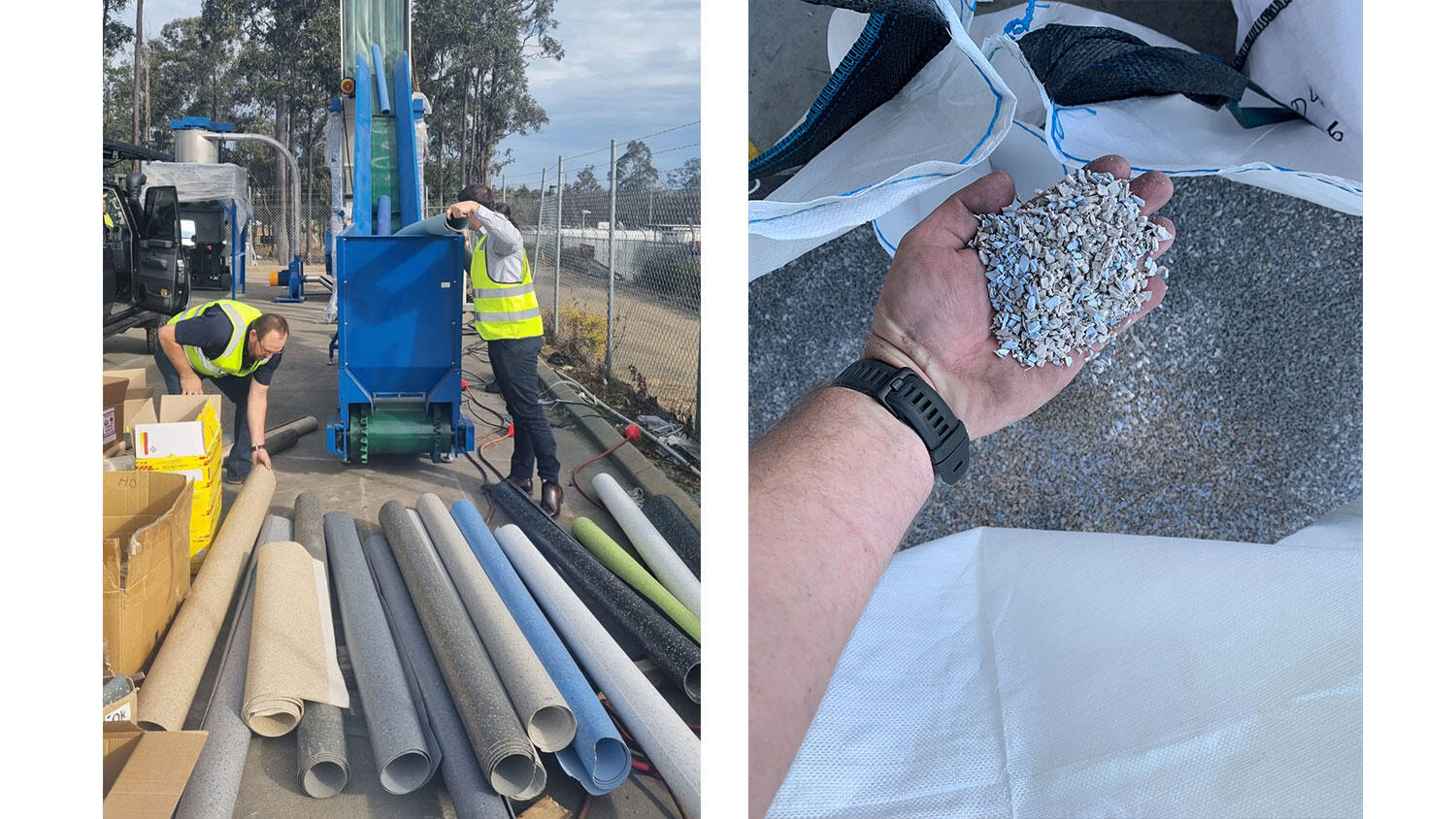

Restart® in Australia

Tarkett Australia is proud to offer local customers a truly circular solution to their flooring waste. Through local investment in processing machinery alongside key partnerships with logistics and suppliers, Tarkett Australia can collect and divert flooring offcuts and select post-use waste from landfill. This valuable resource is processed in Australia and returned to our factories to be turned back into high quality flooring, effectively closing the loop on flooring ‘waste’.

Investment in local capabilities was required to process our waste flooring for both shipping efficiencies, and in preparation for recycling at our plants. This investment has been a journey involving several parties and included grant funding from the NSW Environment Protection Authority’s (EPA) Bin Trim program. The combined efforts of all parties have delivered a functional system that will allow local construction greater access to make sustainable product choices.

We’ve also developed unique techniques for turning old carpet tiles into new ones thanks to our innovative method of separating the yarn from the backing, making both materials 100% recyclable. Thanks to our partnership with Aquafil, we’ve fully closed the loop on carpet, recycling the salvaged yarn into high-quality new yarn, ready for use. Because recycling is about collaboration, which is why if a material can’t be safely recycled into flooring, we look for partners in other industries who can use it in a different way.

Sound impressive? Maybe. But we see it more as common sense. Because tackling climate change and resource scarcity is an imperative that demands a total commitment to a circular economy. And at Tarkett we’re completely onboard. By choosing a Tarkett flooring solution, you’re choosing a company with a proven track record of trailblazing recycling schemes and innovative recycling solutions. Peace of mind that your choice is a good one.

* Homogeneous vinyl flooring produced from 2011 onwards

Making conscious choices. For people and planet.

Tarkett Human-Conscious Design®.

8 recycling centres

We have eight dedicated recycling centres around the world and we recycle carpet tiles, linoleum and vinyl flooring

Post-use recycling

We are the only manufacturer in Europe to pioneer closed-loop recycling for post-use carpet tiles, linoleum and homogeneous vinyl

Green buildings labels

Recycled materials are a positive indicator when aiming for green building certification, like LEED, WELL and BREEAM

Featured articles

Download our sustainability report

More sustainable stories

Climate and circular economy

We’re committed to creating a circular economy. Closing the loop on waste, preserving natural resources and reducing the impact of climate change.

Good materials

Relentless scientific testing of materials and radical transparency for your peace of mind.

Indoor air quality

Leading the way in Indoor Air Quality, so you can breathe easy.